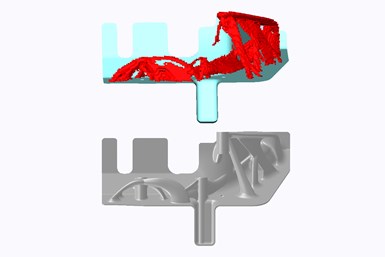

Simulation model. Top photo shows optimized simulation result, while bottom photo shows CAD solution based on the simulation data. Source: GRM

GRM, a TriMech Group company, recently participated in a two-year OverHiPP (overprinting with high-performance polymers) project funded by Innovate UK which focused on developing and optimizing a new hybrid manufacturing technique for overprinting 3D printed material onto composite sheets.

Overprinting is a new approach that takes the benefits from a number of existing techniques, specifically from overmolding, resin transfer molding (RTM) and 3D printing. The benefits of this approach include low tooling costs, increased flexibility, rapid changeover of material and low material waste. One challenge with it, however, is the limited knowledge and technologies available.

Recent developments in five-axis 3D printing hardware have enabled projects to push the technological limits further by reducing the need for support structures, enabling manufacturing shapes not previously possible, even with conventional 3D printing, and, pertinently, overprinting material onto existing components. However, simulation techniques for such 3D printed structures have not developed at the same pace, the company says. This is a key area that GRM has been working on solutions.

GRM Consulting is a specialist design and topology optimization software company, with extensive knowledge and experience in developing finite element analysis (FEA) programs across a wide range of disciplines. The company has been developing new software for the OverHiPP project to provide insight, guidance and confidence in 3D printed components by improving the accuracy of digital twins.

The tool path and infill patterns make 5-axis 3D printed structures highly anisotropic in nature. This can make it difficult to accurately model these properties into a digital twin and gain insight into structural performance and failure modes. Moreover, it is almost impossible for a human to manually model the correct material orientation onto each element in an FEA model. GRM has solved this problem by developing software that can automatically replicate a toolpath in an FEA model. Based on a proprietary G-Code reader that can analyze and determine tool path properties before converting it into a digital twin format enables allows for the precise filament orientations and infill cavities to be considered when running structural simulations.

GRM has rigorously tested its results. One such test investigated the feasibility of 3D printing a hyper-car foot rest. This included a number of topology optimization studies being investigated to determine key load paths and structural performance. The final results were interpreted and modelled by GRM for manufacture.

The study aimed to determine the optimal build directions using the minimal amount of material to best support the assessed load cases. From this, a CAD model was then created in SolidWorks based on the topology results, ready for manufacture at the Centre for Additive Layer Manufacturing (CALM) at Exeter University using a high-temperature polyamide from Lehvoss. Local features, such as shoulder bolt mounts, were added and design for additive manufacturing (DFAM) drawings were generated.

It was clear from both the simulation and test results that a five-fold difference was found in both the stiffness and strength performance when printing in poor and optimal directions.

As part of the OverHiPP project, GRM has enabled users to virtually model and analyze 3D printed structures at a level of detail never seen before. An accurate digital twin can now be generated, enabling precise design decisions to be made, by creating updated Nastran/Abaqus models. All of these software features have strong correlation to physical tests, proving their validity. Different printing strategies can now be studied in detail, by assessing weak points and failure modes for each variant before manufacturing offering greater efficiencies in the workflow and more consistent, successful outcomes.